The vortex flowmeter is a professional steam flow meter, the most accurate flowmeter for measuring steam

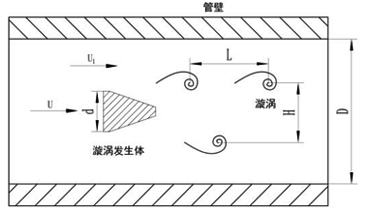

A vortex generator (bluff body) is set in the fluid, and regular vortices are alternately generated from both sides of the vortex generator.

This vortex is called the Karman vortex street, as shown in Figure 1. The vortex array is arranged asymmetrically downstream of the vortex generator.

Suppose the frequency of the vortex is f, the average velocity of the incoming flow of the measured medium is U, the front width of the vortex generator is d,

and the diameter of the surface body is D. According to the Karman vortex street principle, there is the following relationship:

Vortex flowmeter formula: f=StU1/d=StU/md

U1—average velocity on both sides of the vortex generator, m/s

St-Strouhal number

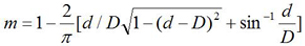

m—The ratio of the arcuate area on both sides of the vortex generator to the cross-sectional area of the pipeline

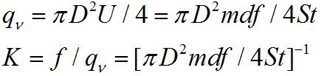

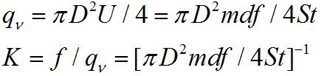

The instantaneous volume flow vortex flowmeter formula is:

Where K is the meter coefficient of the flowmeter, pulse number/m3 (P/m3)

In addition to the geometric size of the vortex generator and the pipeline, K is also related to the Strouhal number. The Strouhal number is a dimensionless parameter, which is related to the shape of the vortex generator and the Reynolds number. Figure 2 shows the relationship between the Strouhal number of the cylindrical vortex generator and the Reynolds number of the pipeline

It can be seen from the figure that in the range of Re=2×104 ~ 7×106, St can be regarded as a constant, which is the normal working range of the instrument

sales01@cxflowmeter.com

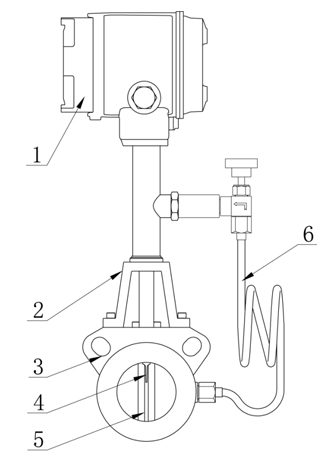

Structure and composition:

1. Converter 2. Support rod 3. Sensor housing 4. Detection element 5. Vortex generator 6. Temperature and pressure compensation device (including: temperature sensor, pressure sensor, shut-off valve, condensing elbow)

product features:

1. The pressure loss is small, the measuring range is large, and the accuracy is high;

2. It is hardly affected by fluid density, pressure, temperature, viscosity and other parameters when measuring volume flow under working conditions;

3. There are no movable mechanical parts, so the reliability is high and the maintenance is small;

4. The instrument parameters can be stable for a long time. This instrument adopts piezoelectric stress sensor with high reliability and can work in the working temperature range of -25℃~+320℃;

5. A wide range of applications, the flow of steam, gas, liquid and other fluids can be measured;

6. Humanized menu and interface based on dot matrix display, with bright backlight, supporting both Chinese and English languages, suitable for various customer groups;

7. Support temperature and pressure measurement to facilitate the needs of gas medium temperature and pressure compensation;

8. Support flow rate conversion display function, which is convenient for viewing the current flow rate on site;

9. Supports split-screen display function, which can enlarge the screen to display single or two parameters (temperature, pressure, working conditions, flow rate and flow rate of standard conditions, etc.);

10. Simulation output function, support 4-20mA current simulation, frequency output simulation, convenient for on-site non-real current debugging;

11. Support 4-20mA output, pulse (equivalent) output, alarm output, RS485 communication output;

12. Both the two-wire system and the three-wire system are separately DCDC (DC1000V) isolated;

The main technical parameters:

Measuring medium gas, liquid, steam

Executive standard: Vortex flow sensor (JB/T 9249-1999)

Verification Regulations Vortex Flowmeter (JJG 1029-2007)

Connection method: card-mounted, flanged

Nominal diameter DN25, DN32, DN40, DN50, DN65, DN80, DN100, DN125, DN150, DN200, DN250, DN300

Flange standard Conventional standard GB/T9113-2000

Other standards International pipe flange standards such as German standard DIN, American standard ANSI, Japanese standard JIS

Domestic pipe flange standards such as the standards of the Ministry of Chemical Industry and the Ministry of Machinery

Verification conditions Verification device Sonic nozzle flow rate verification device

Accuracy level 1.5

Turndown ratio 1:10

Flow rate range Liquid: 0.5~7m/s Gas: 5~50m/s

Instrument material: 304 stainless steel, 316 stainless steel

Temperature range -25℃~100℃, -25℃~+280℃, -25℃~+320℃

Pressure rating 1.6MPa, 2.5MPa, 4.0MPa

Output signal Pulse frequency signal

Two-wire 4-20mA DC current signal

485 communication

Power supply 24V DC

Explosion-proof grade Basic type: non-explosion-proof product, explosion-proof type: Exd ⅡBT4

Protection grade IP65

Environmental conditions Ambient temperature: -25℃~55℃ Relative humidity: 5~90% Atmospheric pressure: 86~106KPa

If you want to know more about vortex flow meter, please consult winny:sales01@cxflowmeter.com